Command the power of robotic forming

Are you searching for a Game-changing solution to the challenges in your forming operations?

Cost Savings: Automated forming helps reduce labor costs associated with manual operations, optimizing production efficiency and minimizing material waste.

Increased Production Capacity: Automated systems can operate continuously, enabling higher production volumes and meeting increased demand without compromising quality or consistency.

Consistent Precision: Automation ensures consistent and precise metal forming, eliminating variations that may occur in manual operations due to human error or fatigue - resulting in improved product quality and reduced scrap rates.

Increased Efficiency: Automated forming with a brake press allows for faster production cycles, reducing the time required for metal forming compared to manual processes.

Improved Safety: By minimizing manual intervention, automated forming reduces the risk of injuries associated with manual handling of heavy or sharp-edged materials.

OUR APPROACH TO ROBOTIC FORMING

Metalcraft Automation Group takes pride in building automation with high quality standards in place for our mechanical and electrical engineering and machine building practices. We design and build robotic forming cells to meet customer needs. We use high-quality, reliable and proven industrial components, and our standardized programming methods help with ease of operation from one system to the next in addition to ease of serviceability.

We design it, build it, program it, and run-off your equipment at our facility to test it and then begin the training process for operators and maintenance personnel. Afterwards, we pack, ship, and install it. Once your robotic forming system is up and running in your facility, we include additional training to ensure your operational success. Upon completion, we deliver a document package with operator and maintenance instructions, a complete list of components with recommended spare parts and wear items noted, PLC programs and robot programs. We provide a 12-month limited warranty that covers quality of workmanship and system operation. We also follow up with service and continued support to ensure long-term reliability and sustainability.

WHAT WE DELIVER

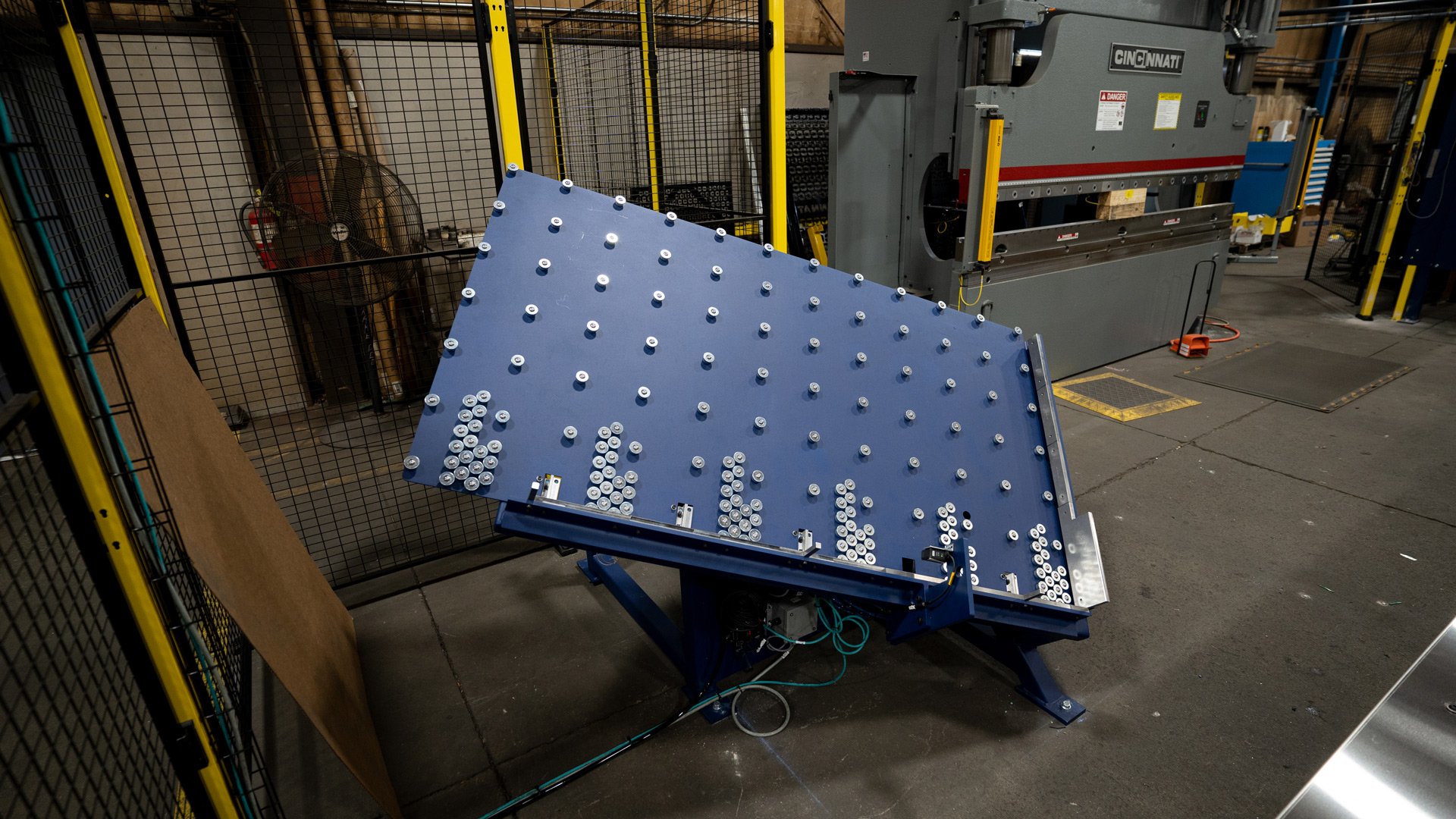

Eliminate safety and ergonomic concerns with Fanuc robots integrated with Cincinnati Press Brakes

Increased throughput

Flexible EOAT (End of Arm Tooling) to accommodate multiple part variations

Quick change EOAT (End of Arm Tooling)

Robotic track units to increase robot reach zone

Flexible inbound/outbound cart systems

Reliable and consistent part quality which drives increased quality to downstream operations

Optional robotic gantry supermarket feeding/forming robot

Bring Automated Operations into Your Work Place

To learn how Metalcraft Automation Group can improve your manufacturing processes, contact us today!